Strauch Fiber Equipment Co.

We Handcraft It All With You In Mind.

How We Produce our Drum Carders: Technical Information About Drum Carders

The True Facts About the Components and Methods We Use To Produce Our Drum Carders

Regarding Durability

Remember, the more complicated a drum carder is, the more prone it is to breaking down--just ask any sports car or boat owner.

The Unique Licker-in Drum

The purpose of the small drum is to transfer fiber to the large drum. The blades "push" their way through the fibers, grab them and flick them onto the rotating large drum. The very smooth blades pre-align the fiber and make transfer to the large drum more complete with minimal fiber buildup on the small drum and most importantly, no damage to your precious fiber. If you put regular carding cloth on this drum, the tendency is for the fiber to hold on and wrap around, not what you want the infeed drum to do!

Since all other manufacturers use standard card cloth on BOTH drums, fiber wrap around is a constant issue.

Special Drum Construction

Fine Cloth on the Large Drum

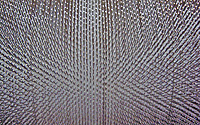

We have evaluated many different styles and pin densities of carding cloth on the Strauch carders and found that the 128 teeth per inch (#05 fine) carding cloth is the best and most versatile for carding all the various fibers now available to hand spinners.

Regarding Drum Balance

All of our chain drive carders are so well designed and constructed as to be "free spinning." With the Brush Attachment up, give the crank a good spin and the drums will keep turning on their own for 5-6 revolutions. You will also notice that the machine is quiet! The teeth of the drums do not intermesh.

Card Cloth Installation

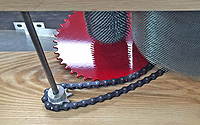

Chain Drive

It is a simple, trouble free method used for the past 30 years and is far less complicated than counter-rotating gears.

The chain is not lubricated nor should it be. There are NO adjustments necessary. It's designed to run dry so that fiber will not stick to it. Furthermore, with proper care while carding, no fiber will get onto the chain, sprockets or bearings.

Special Bearing Blocks

Ball bearings are an over-kill. Unlike the wheel of a spinning wheel, the drums of a drum carder do not rotate continuously at a high speed. The impregnated bushings we use are more than sufficient and do not have moving parts like ball bearings. Remember the comment we made above regarding complexity.

Placement of Brush Attachment

The brush swings out of the way for convenience and easy batt removal.